I was a Kickstarter backer for the FLEKS3D system, which claims to address 3 common FFF issues:

- Releasing finished parts from the build plate

- Gripping the build plate with no warping

- Leveling the plate between each print

Admittedly, their Kickstarter wrapped up quite a while ago (oops!), but I finally took the time to give it a go and see if the performance lives up to the points above.

Scrappybot with some gnarly BuildTak. The print surface is in need of some TLC.

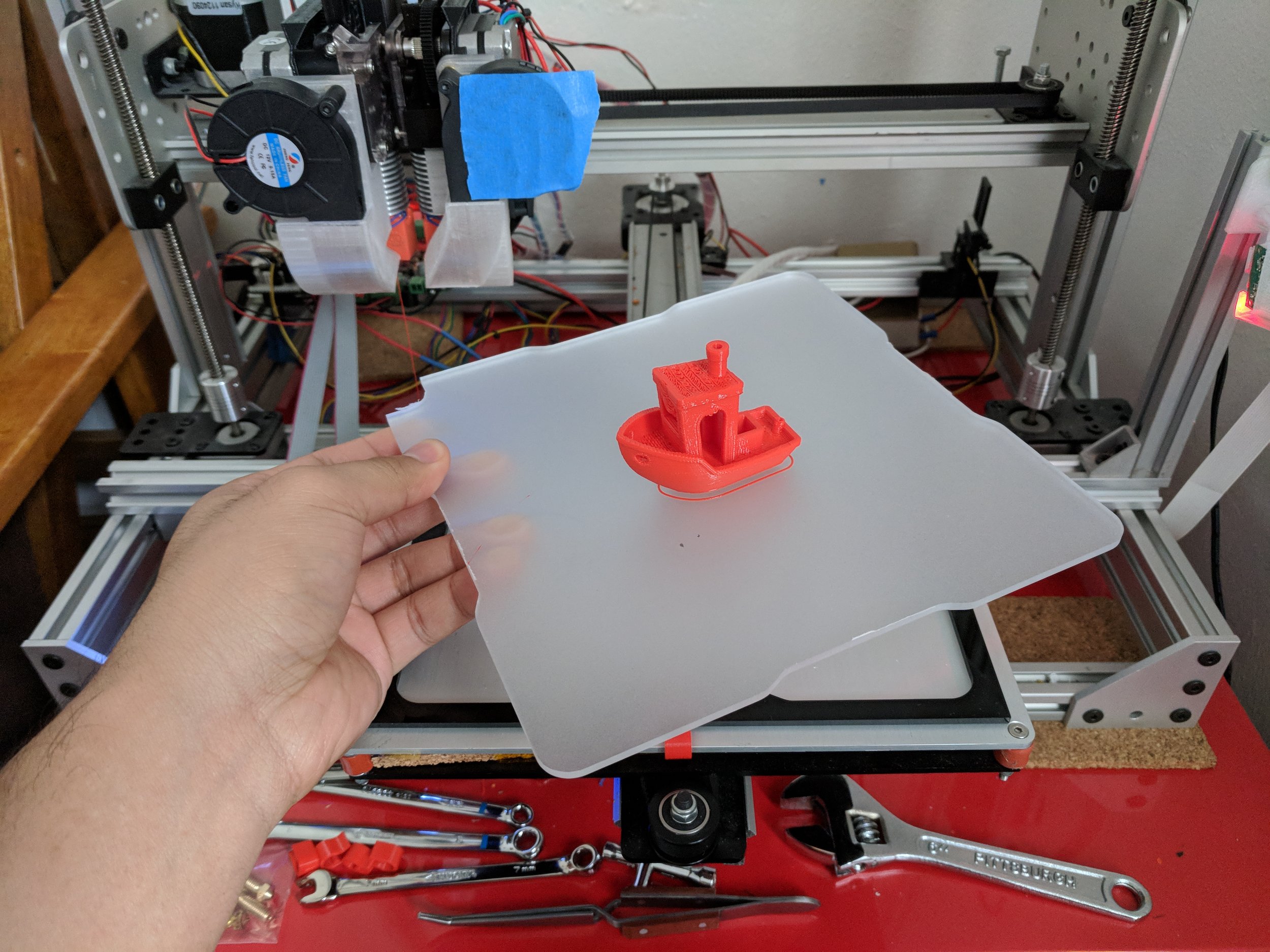

The FLEKS3D system, consisting of the RapidFrame on the outside with the flexible plate on the inside.

They address the first point, releasing parts from the build plate, with their flexible plate. This is available as a stand-alone add-on, or as part of the FLEKS3D system, which includes the RapidFrame adapter and an extra FLEKS3D plate for hot swapping. Once the part finishes printing, users can detach them by bending the plate. I was nervous about applying any sort of bend on the plate at first, but I found that this actually worked pretty well! I've been used to more rough handling with a sharpened scraper and hammer in times past, so this is a welcome change.

My obligatory Benchy revealed that my printing temperature was too high!

Bend the plate a bit and it will pop off, or detach enough to easily remove by hand. Any remaining plastic is easily removed with a scraper.

The next point, letting the printed part grip the plate with minimal warping, is addressed by the build plate's rough texture. I'd say that this approach is fairly common when considering other peel-and-stick print surface products, but the FLEKS3D website does say that they employ a proprietary method to achieve the texture on their plates. Regardless, my PLA parts have printed well so far, and I have no complaints in this regard.

Finally, this product hopes to address tedious bed leveling procedures between prints, presumably from people being rough on the build plates when removing parts. FLEKS3D gets around this completely by allowing users to remove and replace the plates. 3D printer users who print on glass plates attached with clips are probably used to this process, already. While I don't typically experience bed leveling issues, I do enjoy this approach so far as well as the other things it affords, such as being able to easily swap the used plate with a new one to resume printing immediately, or being able to hold the plate apart from the printer and scrape off any filament stragglers.

The plate is easy to remove by hand.

Hot swap the plates to start printing your next part immediately.

After my first several uses with the FLEKS3D system, my first impressions include a few pros and cons:

PROS-

- Installation is simple - just clip it on

- The textured surface is great at helping prints stick (good news for you folks using hairspray, gluestick, and the like)

- The replaceable plate lets you start new prints immediately

CONS-

- The notch in the corner is unusable in the print area. I believe this applies only for those using the full FLEKS3D system, as opposed to the FLEKS3D Simple.

- Takes some getting used to if you haven't used a removable surface before. My clips aren't very robust, so if I try to scrape the print right off of the plate like I'm used to doing, I'll accidentally move the RapidFrame as well.

FLEKS3D systems currently run for about $50 (RapidFrame + 2 flexible plates), which may or may not be worth it to you. There is something to be said, I think, about time and cost savings from hot-swapping build plates and not using consumables like tape, spray, or glue.

I still need to test this plate with other materials, since I do tend to change that up depending on the application, but its good compatibility with PLA leaves me confident that I'll be able to print comfortably with that as my workhorse material. Something to mention is that the documentation on my Kickstarter-age kit mentions using the system with no heated bed, in case of warping on the build plate. Their website, however, says that they will perform reliably below 80C, so I will take that into consideration while trying other materials, too.

There are of course multiple players in the flexible build plate market, including Print-in-Z, BuildTak, and Prusa3D, but so far the FLEKS3D system looks like a solution that will remain a solid competitor.