Technical knowledge, engineering, & expertise

My formal technical background is in mechanical engineering. Along with my engineering and design degree, I also have professional SolidWorks certification and am a registered Engineer-in-Training in the state of Texas. Naturally, this background goes hand-in-hand with my work in 3D printing. I've used it for mechanical designs, product development, analyzing 3D printing systems and processes, and more. My depth in these areas has opened up several opportunities for growth in thought leadership, as well.

Project: Scrappybot

Time frame: Winter 2015

Collaborators: N/A

Category: Technical knowledge & expertise

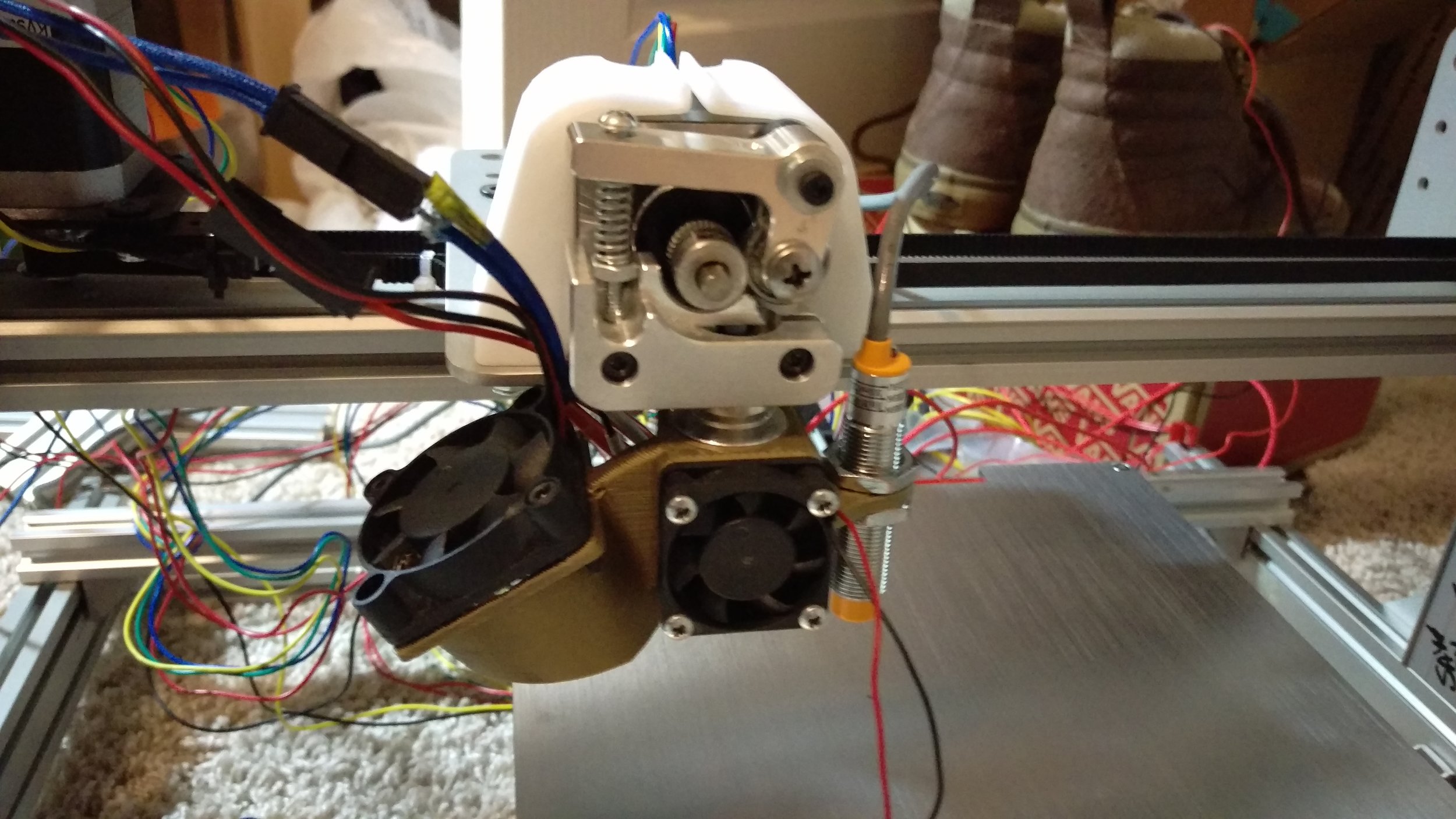

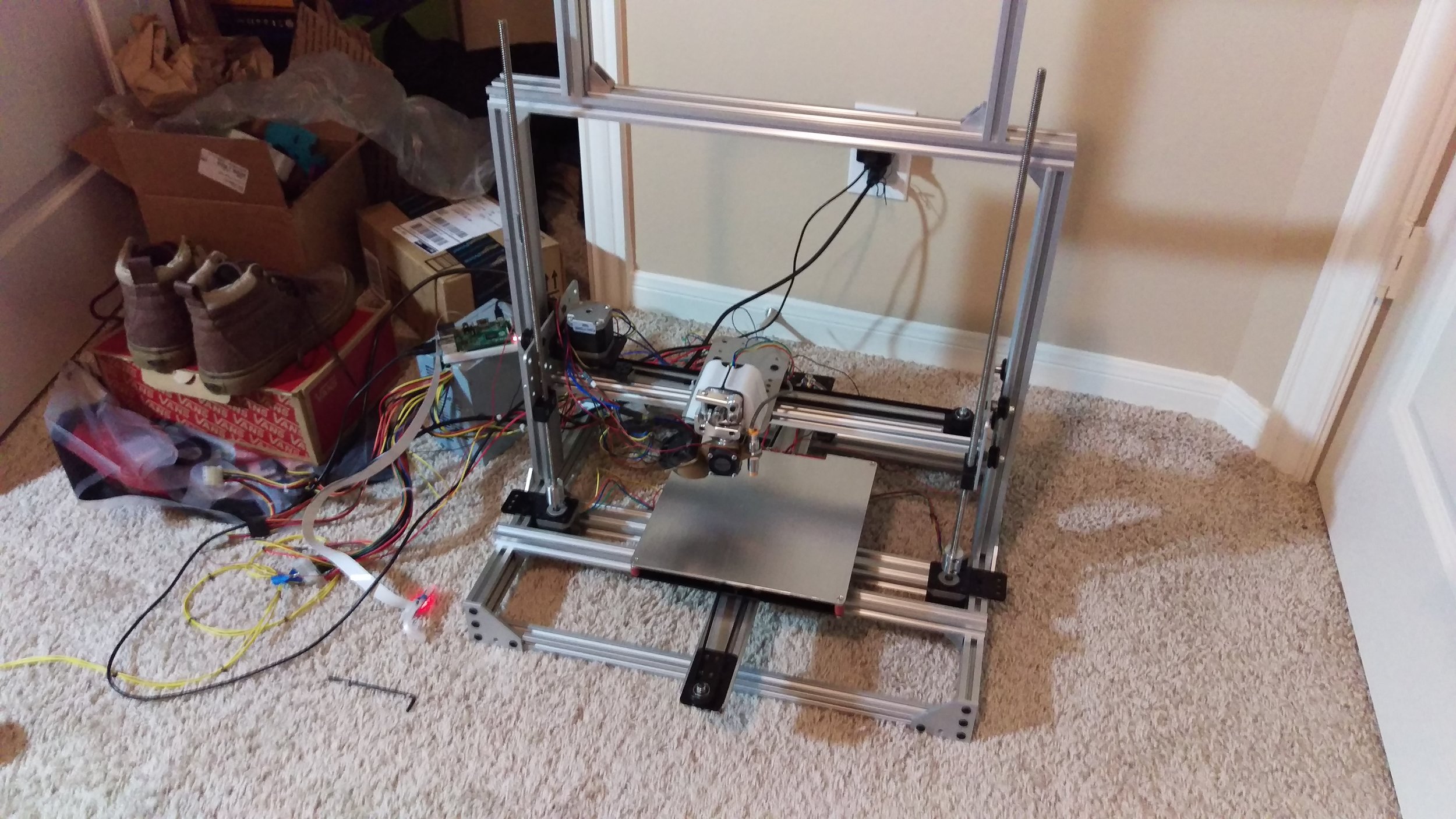

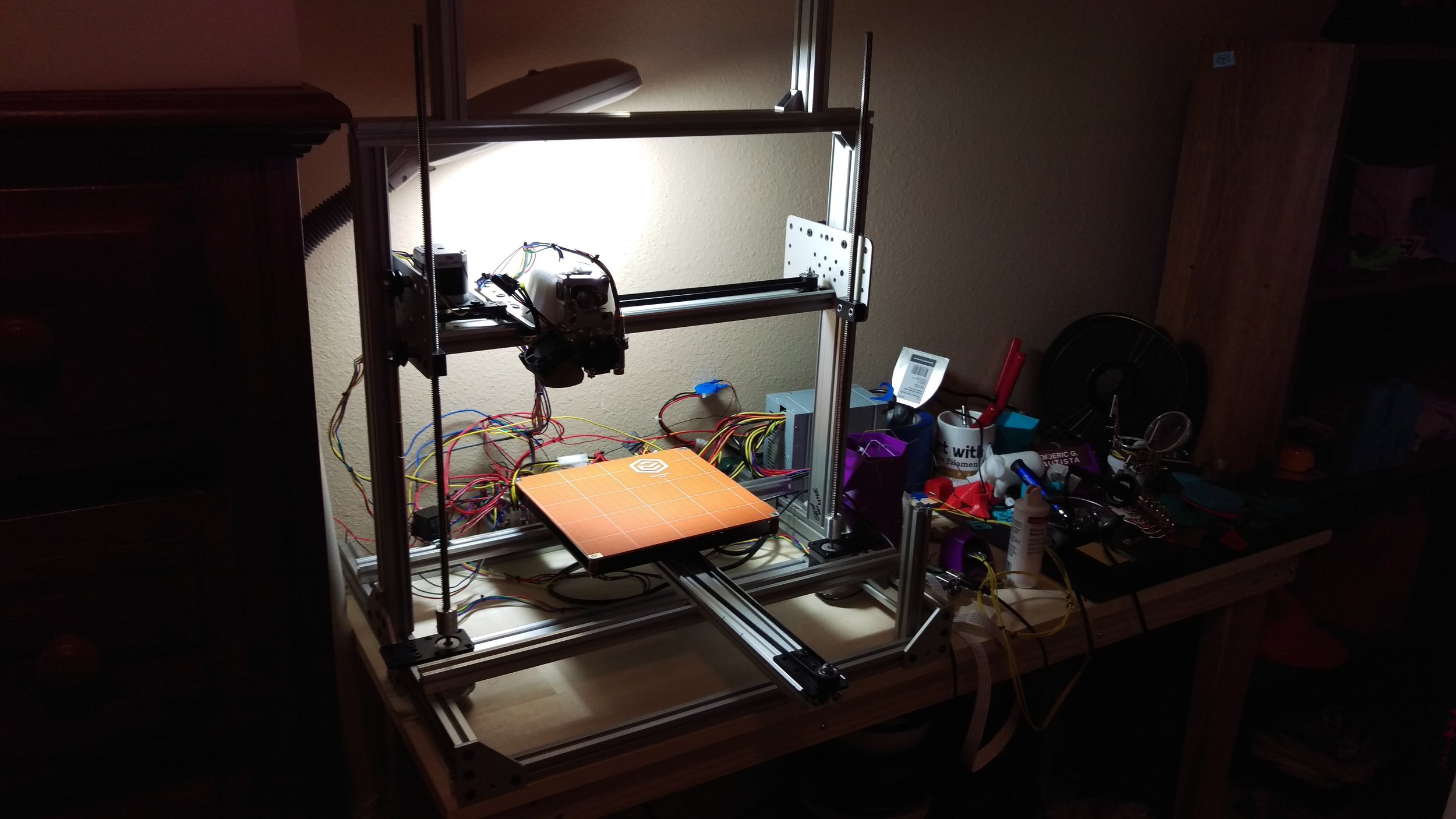

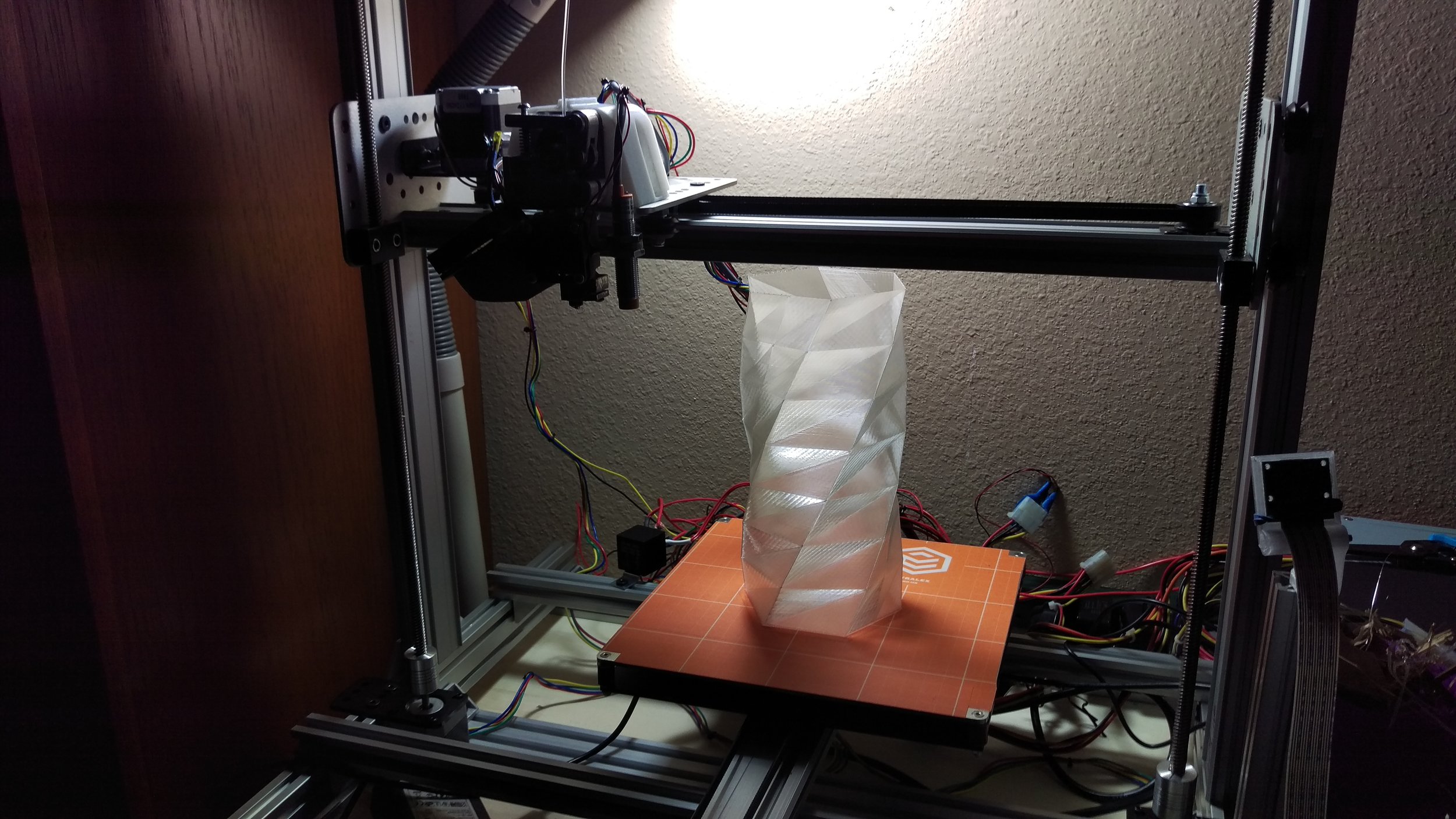

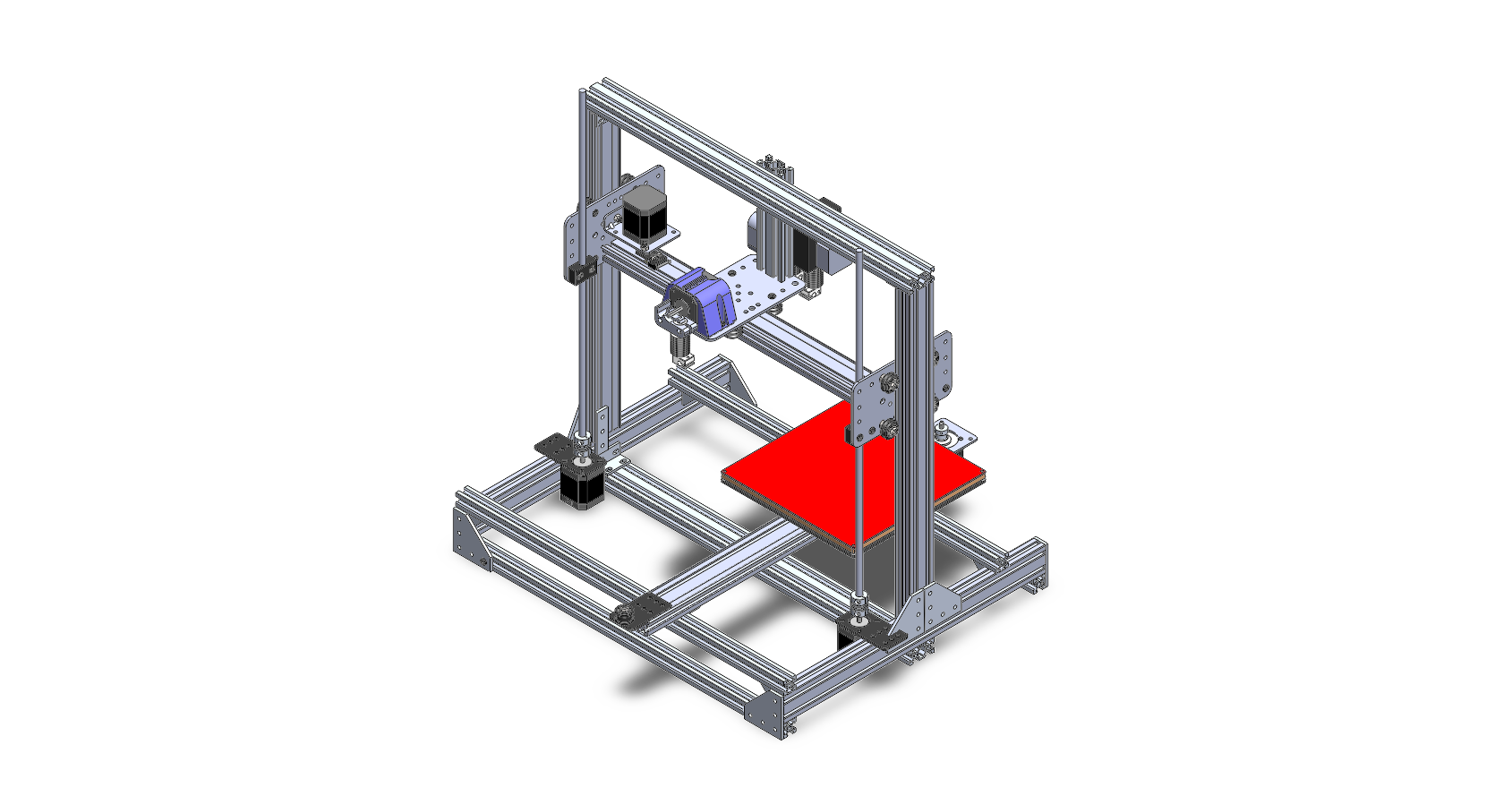

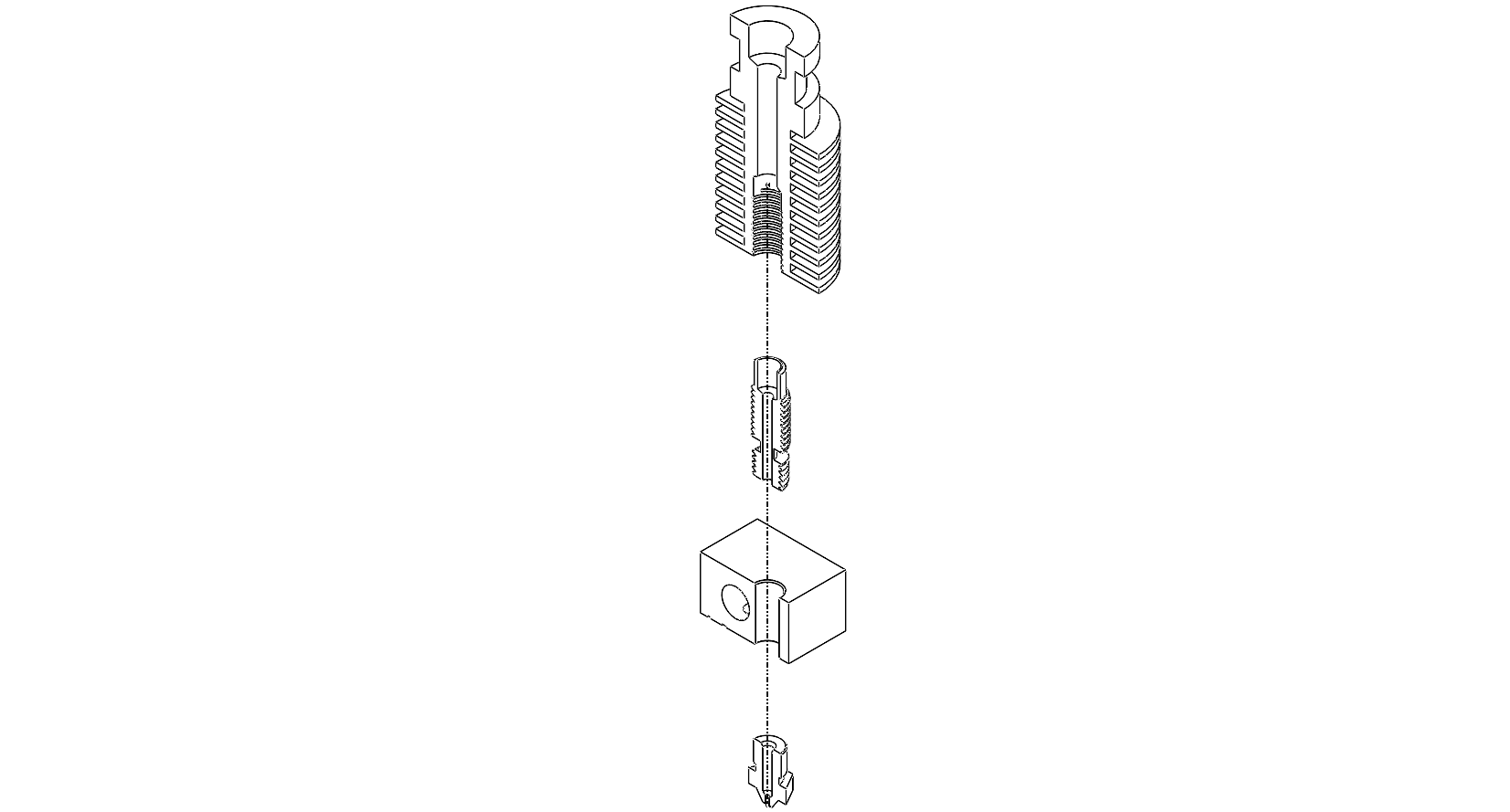

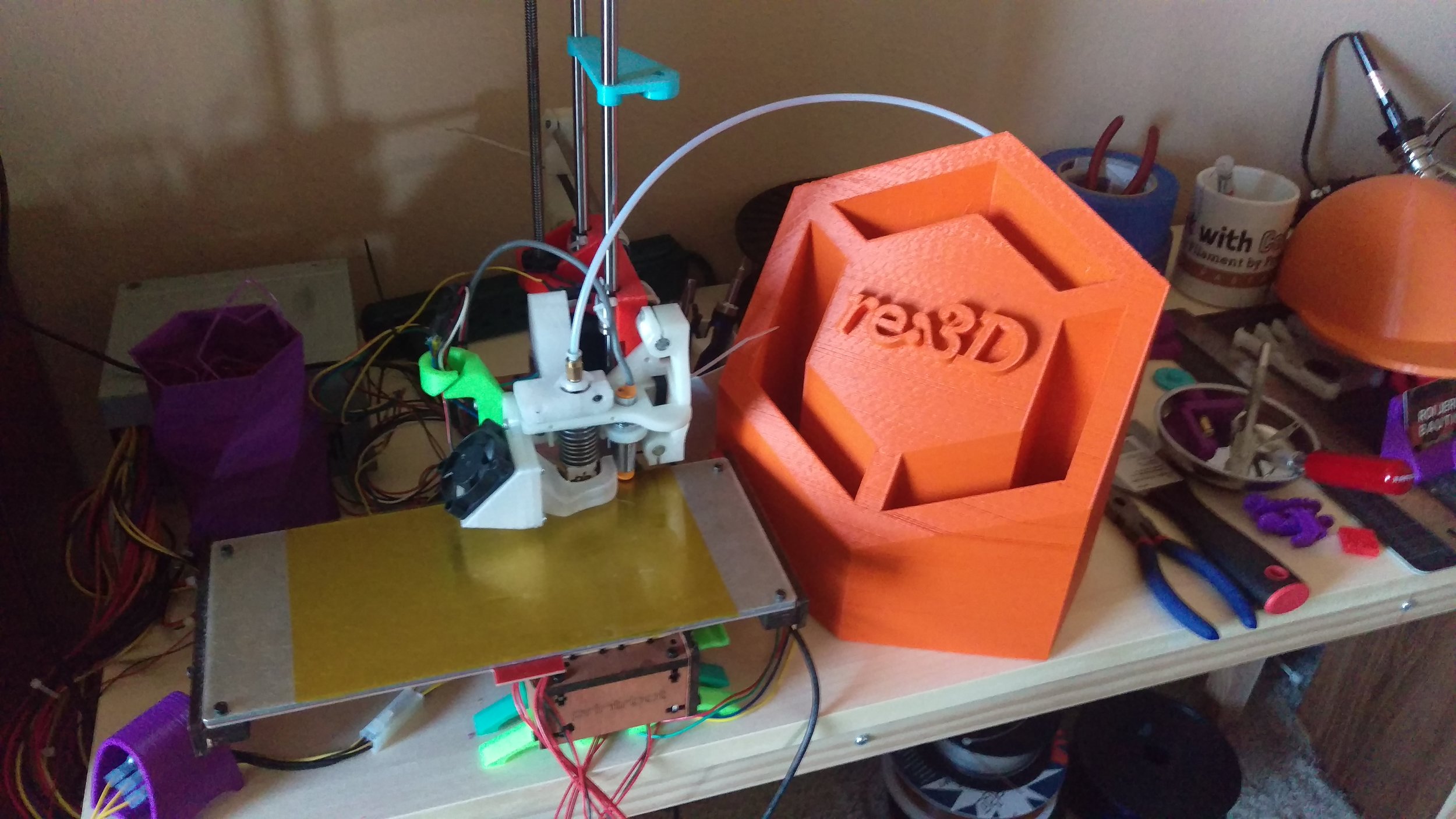

Scrappybot is my deep-dive into FFF 3D printing technology. Built mostly from scrap metal and used electronics, it is an experimental modular additive manufacturing platform. It was used to test hardware, software, and materials, some of which were documented and published on my blog, #jericprints.

- Used SolidWorks to flesh out Scrappybot's mechanical design.

- As a tribute to RepRap style, Scrappybot utilized 3D printed accessories and modifications to make improvements over time.

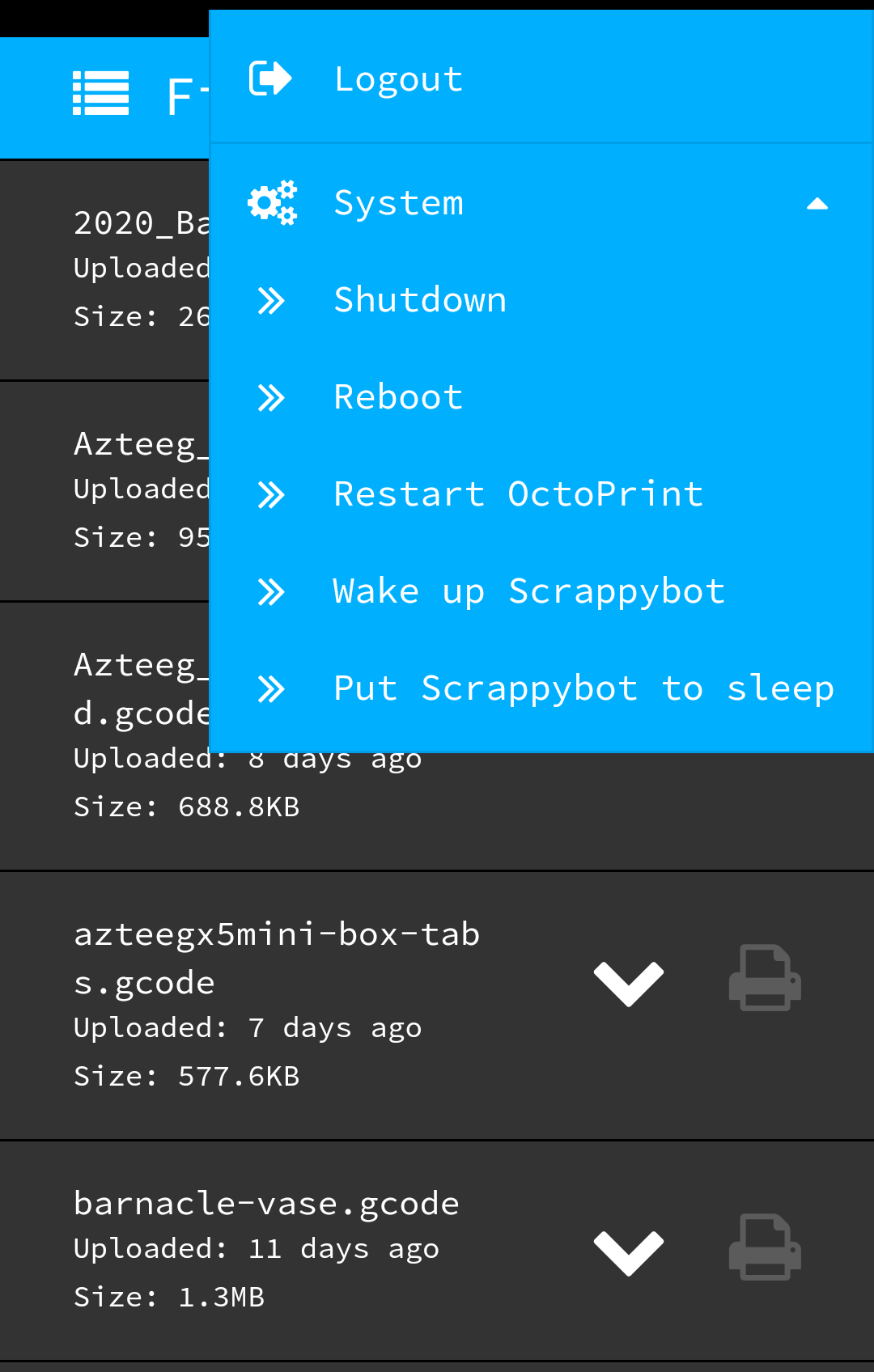

- Using the open source software, Octoprint, Scrappybot was enabled for wireless printing and monitoring, including mobile notifications and remote shut-off.

- With a premium extruder system and all-metal hot end, it is capable of printing high-temperature materials, flexibles, and plastic composites, among other exotic 3D printing filaments.

- Implemented automated bed tramming using an inductive proximity probe and Marlin open source 3D printer firmware.

- Lessons learned from this build have provided a basis for a new machine dubbed "ScrappyCore-XY," which will utilize a different motion platform and implement new and more robust features for higher performance and better usability.

Project: re:3D Engineering

Time frame: Fall 2015 - Present

Collaborators: re:3D teammembers

Category: Technical Knowledge & Engineering

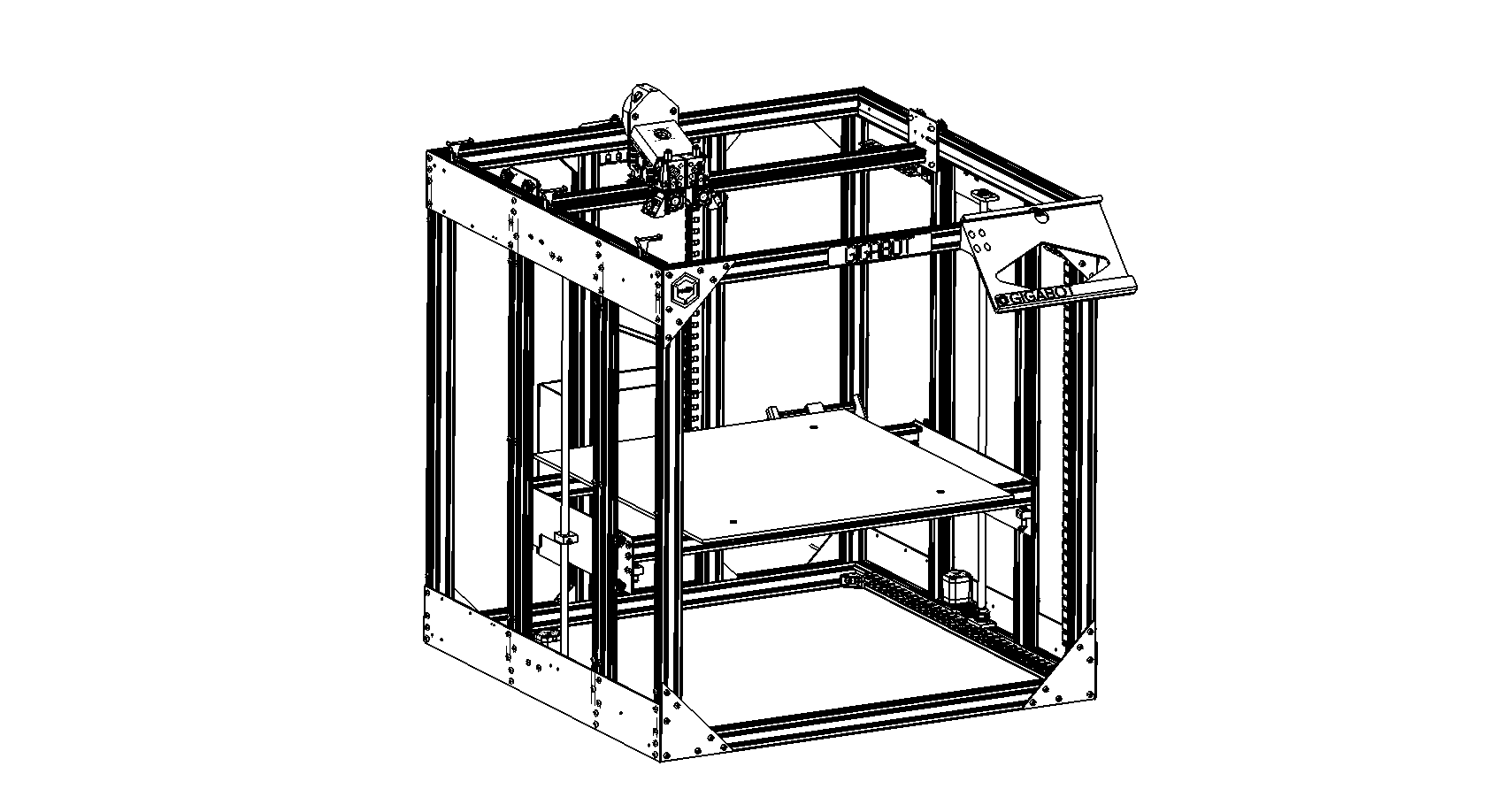

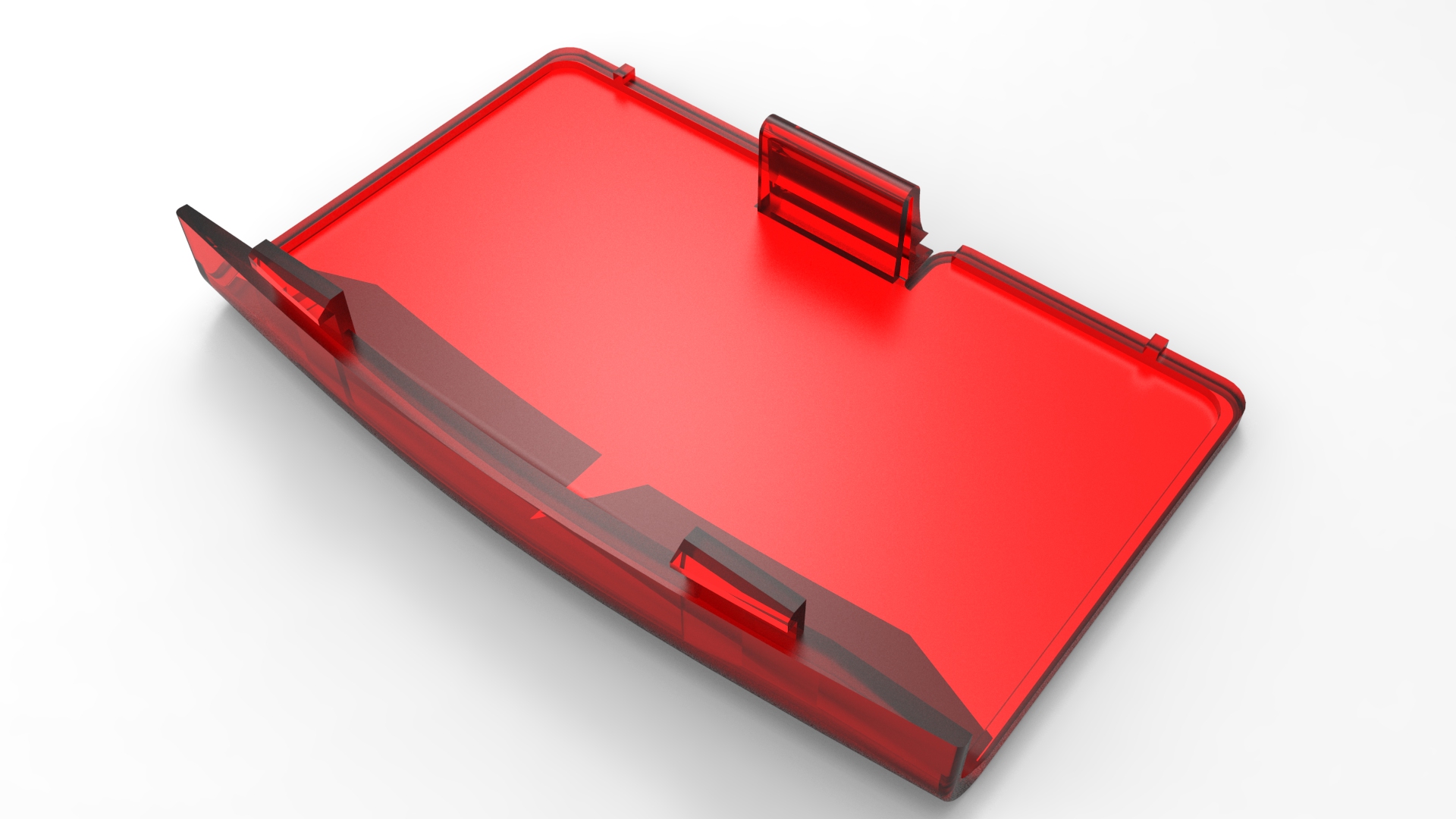

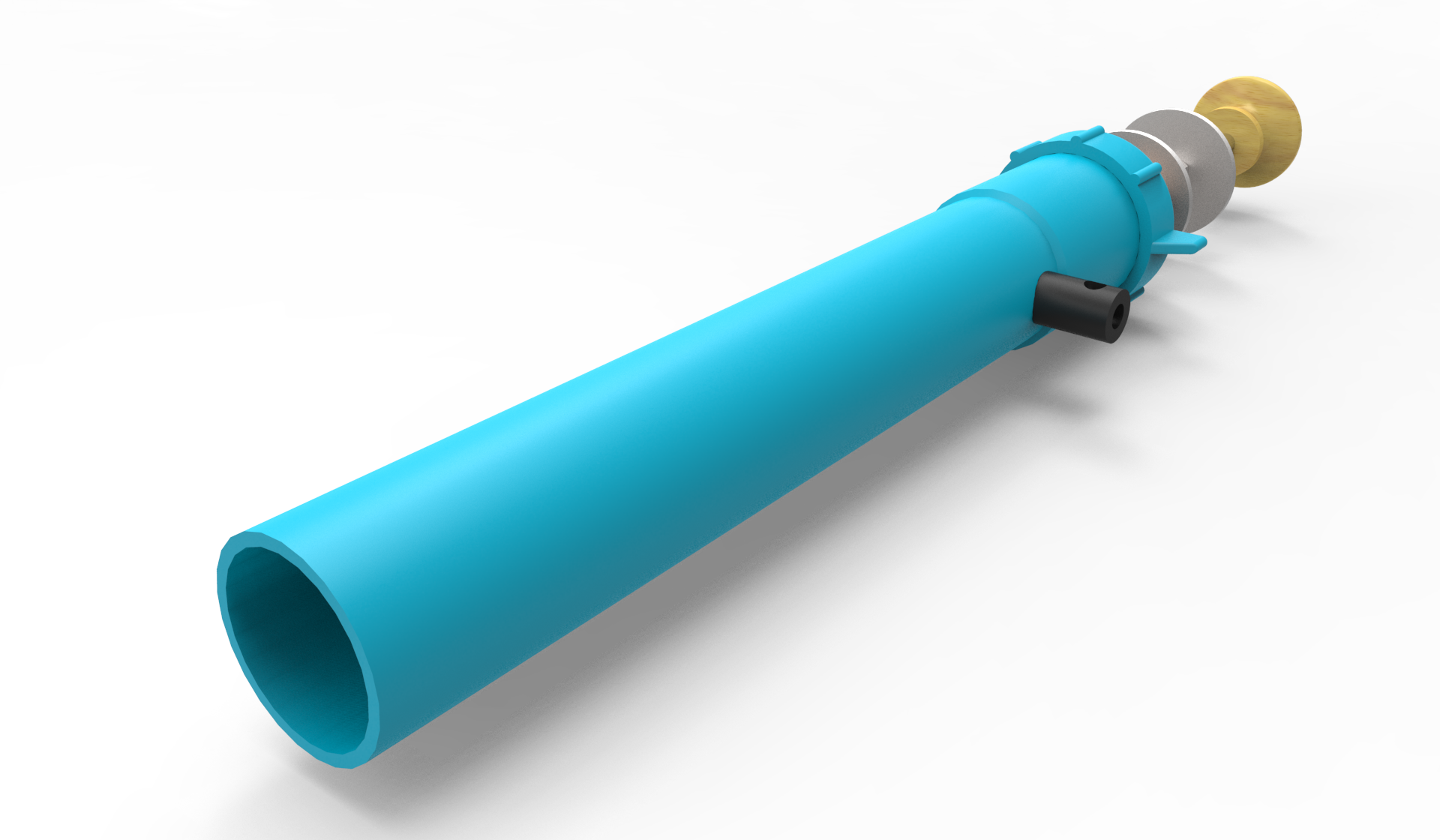

My role at re:3D, Inc. is multi-faceted, employing a depth of knowledge in 3D printing technology, design, and product engineering. In a startup environment, having a well-rounded repertoire of skills has proven incredibly valuable and has allowed me to assume a diversity of roles.

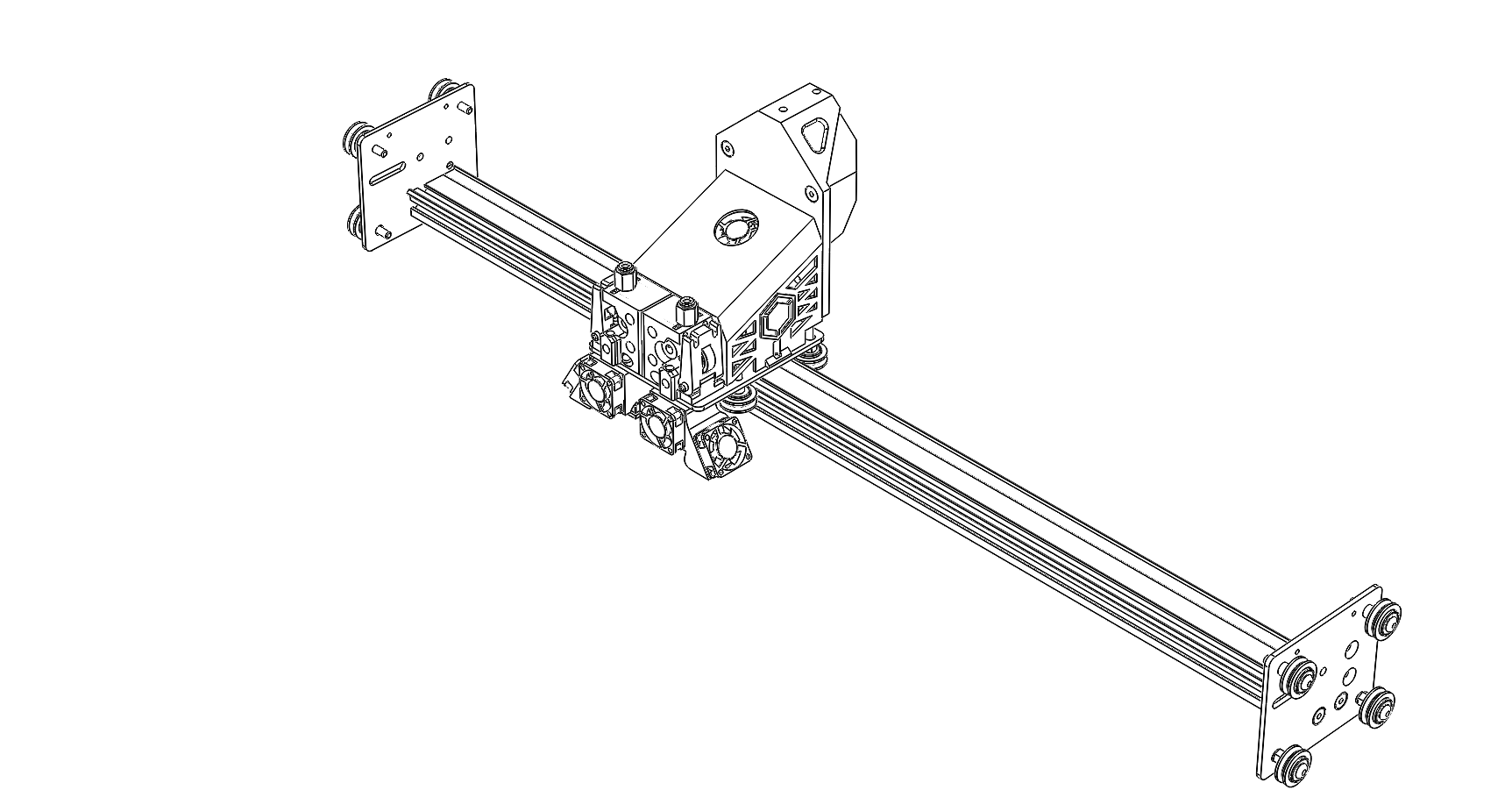

- Performed R&D work for OpenGigabot, Gigabot 3, Gigabot 3+, and currently working to develop the next generation of Gigabot 3D printers.

- Conduct on-site customer training in Gigabot operation and 3D printing software workflow, including design for 3D printing, throughout North America.

- Conduct on-site service visits for repair or machine upgrades throughout North America.

- Generate and maintain internal documentation for R&D and operations initiatives.

- Generate and maintain professional customer-facing technical documentation with continued improvements based on engineering, marketing, and customer insights.

snapshots

Below are examples of work that utilized technical knowledge & expertise.

Below are examples of work that utilized technical knowledge & engineering.